High Rise Whole Building LCA

What:

Where:

When:

For:

With:

Where:

When:

For:

With:

Life Cycle Assessment

San Francisco

2022

NDA

Atelier Ten

San Francisco

2022

NDA

Atelier Ten

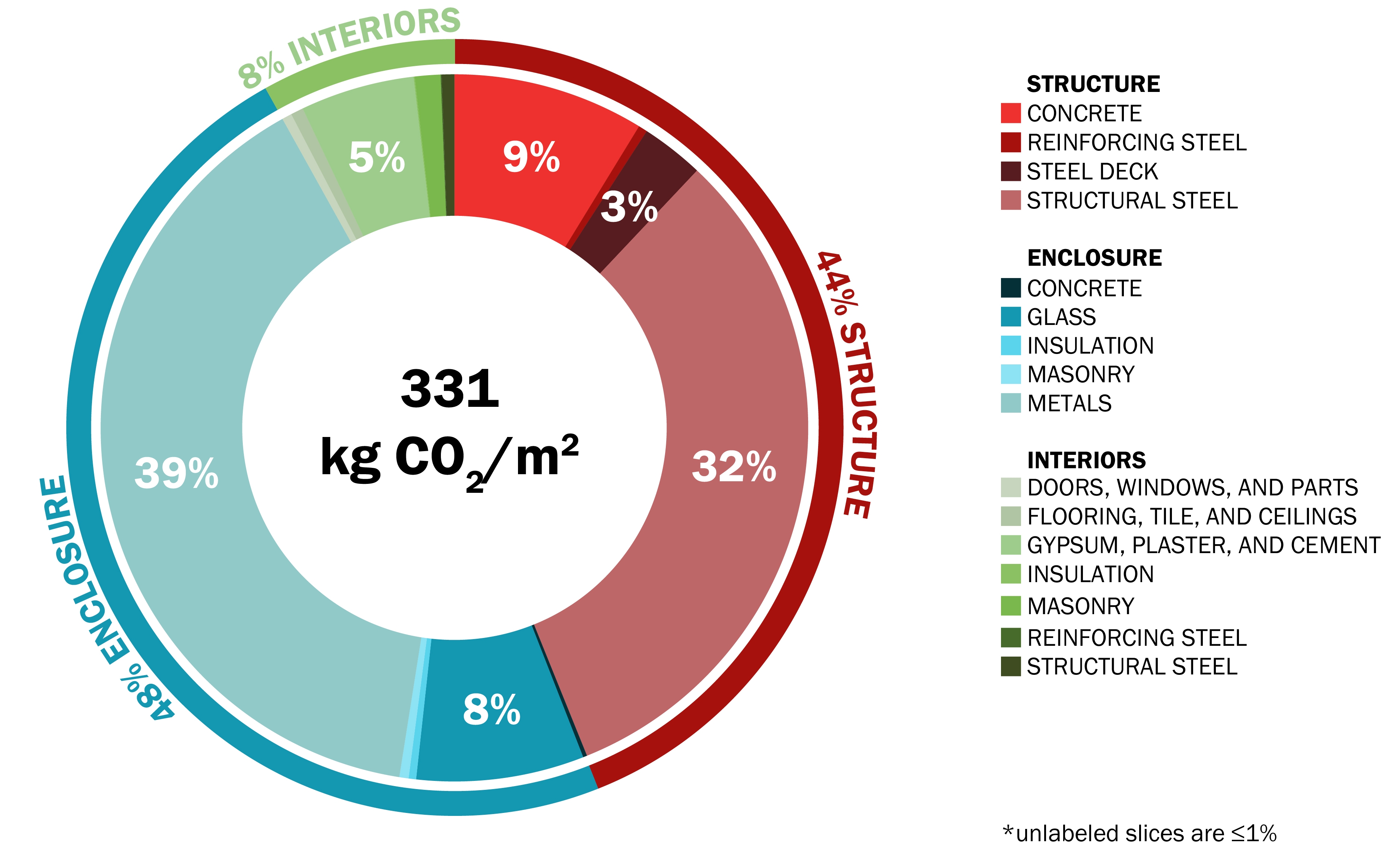

A large developer approached Atelier Ten with the desire to conduct a CD-phase life cycle assessment of a 1,340,000 ft2 high-rise office tower in downtown San Francisco. The project is a renovation of an existing tower, with several new floors being added and wrapped in a new curtainwall facade. The goal of this LCA study was to estimate the carbon emissions saved by reusing the existing structure, as well as to estimate additional savings with smart material choices for the facade, foundation, and structure.

OneClick LCA was used to select EPDs and generate initial carbon data. This data was processed in a specialized graphics tool for creating more detailed and selective graphs.

OneClick LCA was used to select EPDs and generate initial carbon data. This data was processed in a specialized graphics tool for creating more detailed and selective graphs.

A1-A3 Case Comparison

The analysis shows that reusing the foundation and so much of the

superstructure reduced the initial embodied carbon impact of the

project by about 42% compared to if the entire building was built new.Procuring products on the low-end of the typical GWP range can result in a further 39% reduction in embodied carbon.

Built New - A1-A3

Built New - A1-A3High and low estimates were made using client’s calculation methodology, factoring for both quantity uncertainty according to CD phase and material GWP uncertainty:

Built New - Full Scope

Built New - Full ScopeBuilding on the uncertainty analysis for initial emissions, we also estimated the range of potential GWP for the building’s anticipated lifespan of 60 years. Once we account for between three to six replacements for TI Interiors, contents and services (based on lifespan for those elements) we see those elements are just as important as structure and enclosure, nearly doubling the initial estimate of embodied carbon.

Renovation Baseline - A1-A3

Renovation Baseline - A1-A3 Renovation Baseline - A1-A3

Renovation Baseline - A1-A3

Renovation Baseline - Full Scope

Renovation Baseline - Full Scope

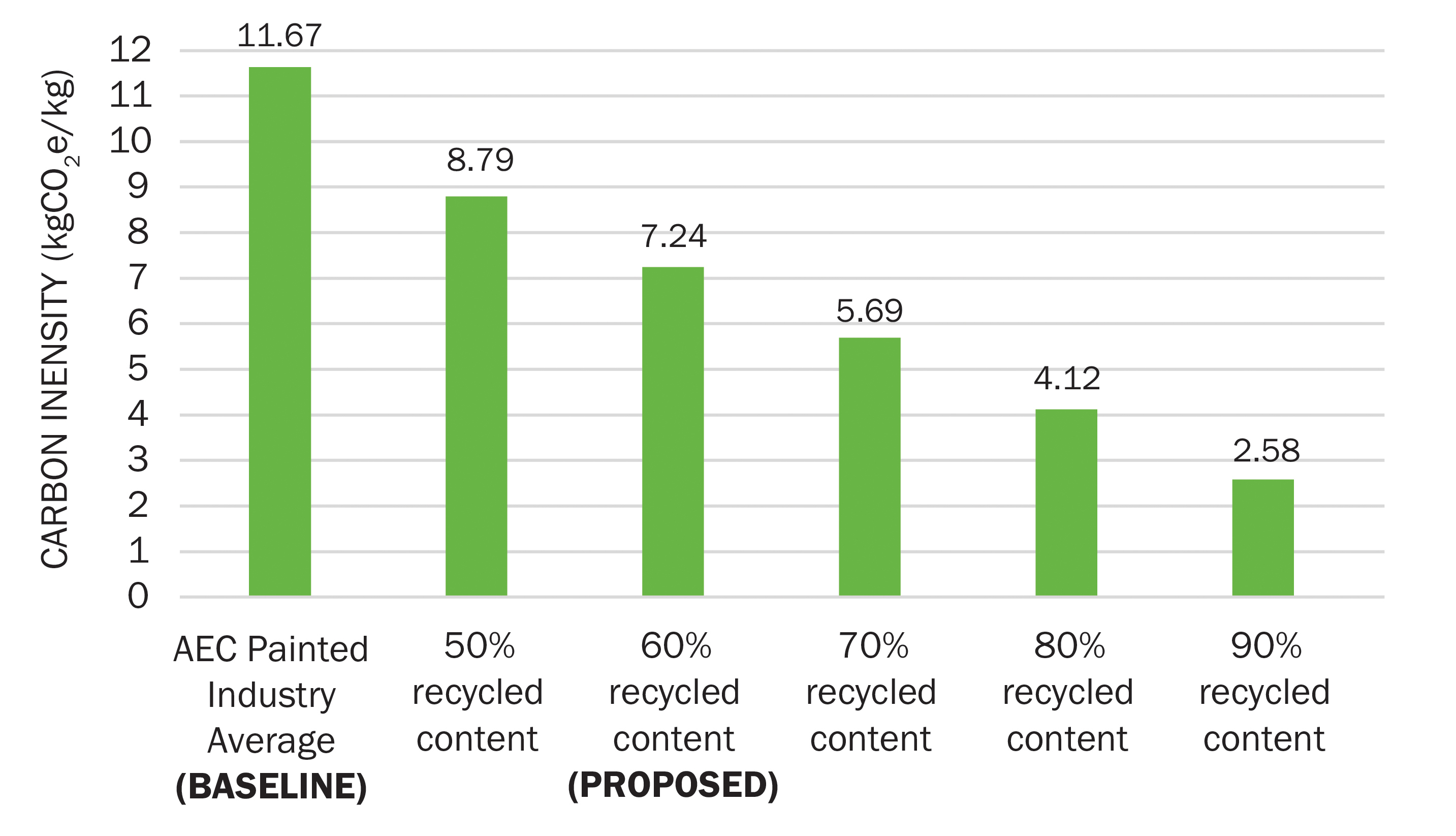

Aluminum Extrusions

Most of the carbon impact of aluminum stems from the production of primary aluminum ingot (billet). Secondary aluminum, made from recycled scraps, has 10x lesser impact than primary ingot. Therefore, the proportion of these components (recycled content) plays a major role in the GWP of the extrusion.

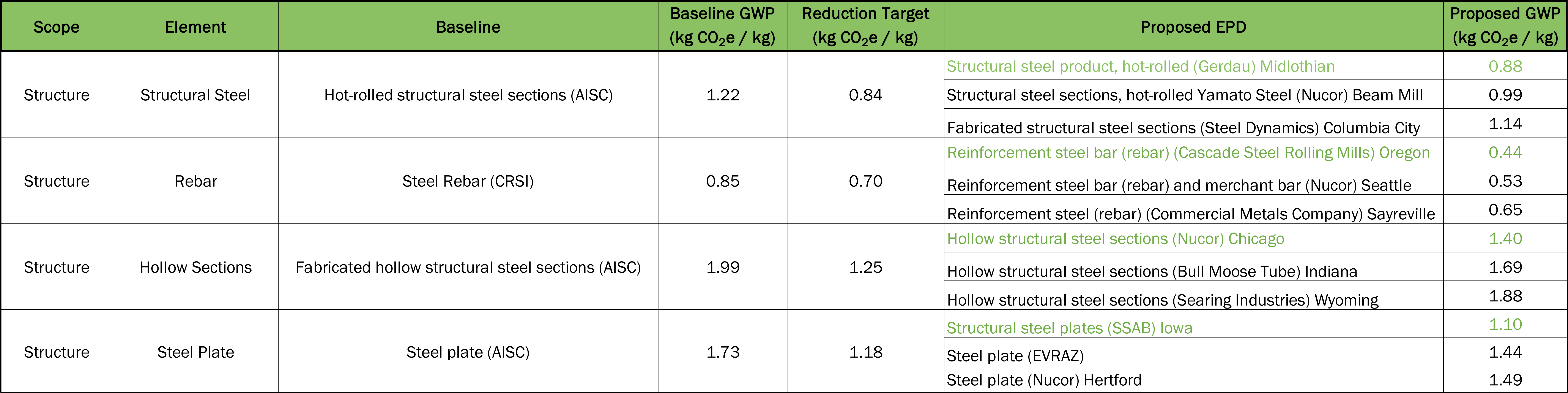

Structural Steel & Rebar

Structural steel and rebar accounts for 33% of the total embodied carbon of the baseline GWP characterizations. Low GWP structural steel and rebar is typically achieved by using electric arc furnaces and high levels of recycled content.

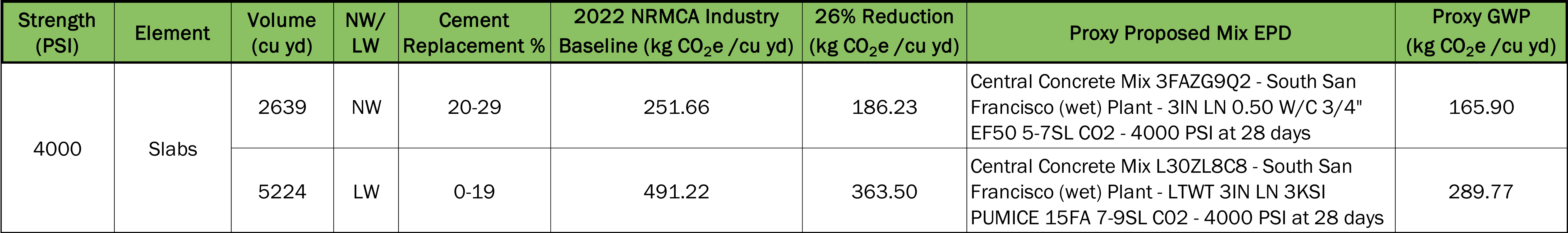

Concrete

Concrete represents 9% of the baseline total GWP, making concrete optimization an essential IRM to reach the GWP target. Concrete optimization requires close collaboration between the structural engineer, contractor, and concrete supplier to ensure carbon targets are met without compromising performance. Some mixes may have higher or lower reductions based on the intended application. Performance-based specifications give concrete suppliers the flexibility to meet all the performance requirements with as low GWP as possible.

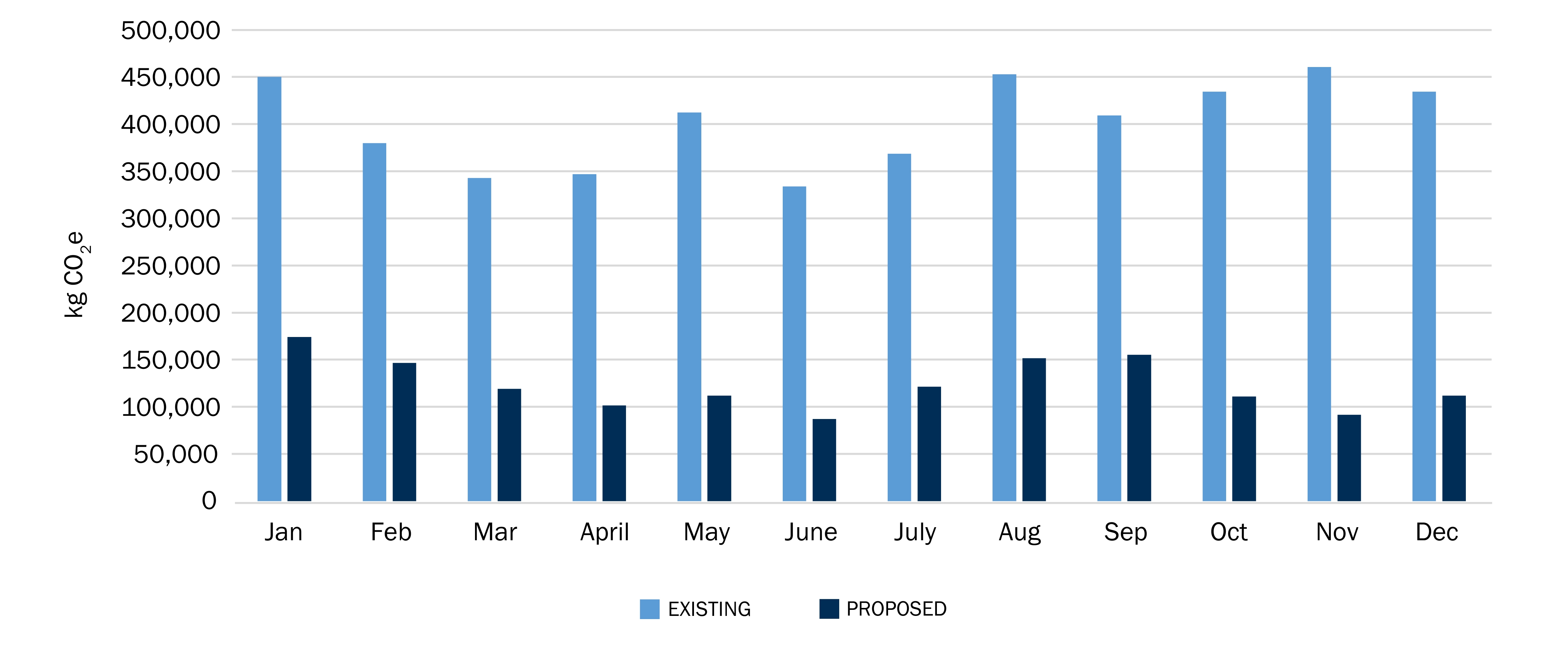

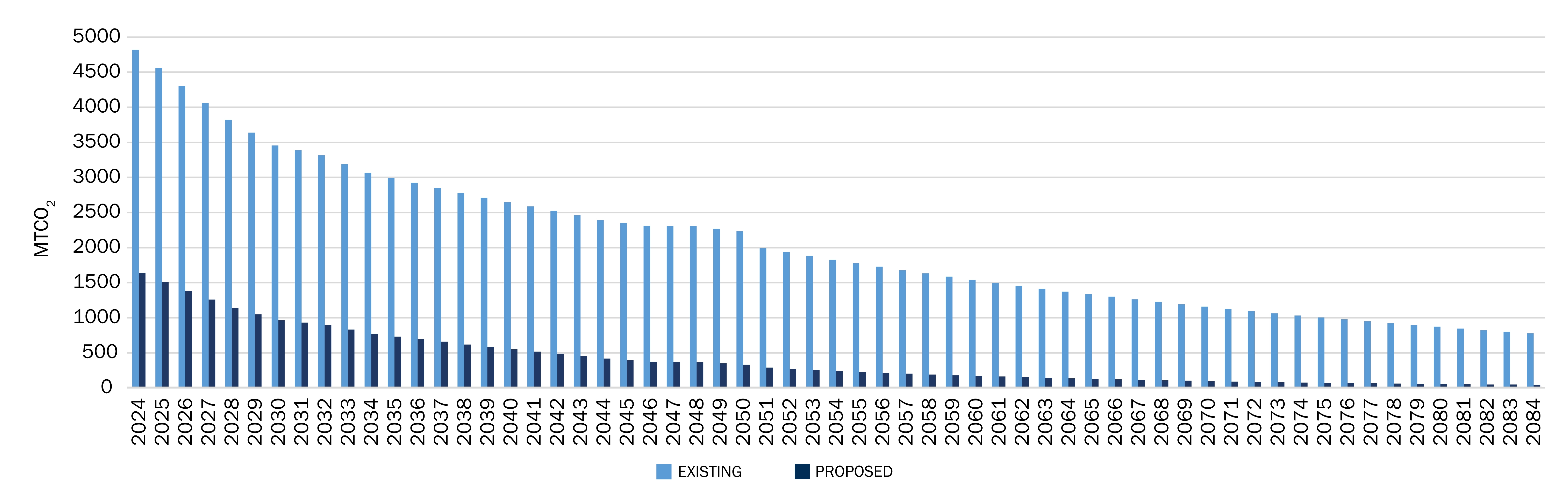

Operational Carbon Projections

The values plotted in the operational energy graphs were estimated using current and projected EUIs, multiplied by carbon intensity factors from NREL’s Cambium database. Operational data projected for life cycle of project - 60 years

Operational data projected for life cycle of project - 60 years