Hydrogen Factory Sustainability Strategizing

What:

Where:

When:

For:

With:

Where:

When:

For:

With:

Hydrogen Capsule Factory

New Mexico

2023

NDA

Atelier Ten

New Mexico

2023

NDA

Atelier Ten

Designed as a 24/7 assembly facility for modular hydrogen capsules to transform the airline industry, this client sought a similarly sustainable factory facility for them to operate from. Atelier Ten recommended several key goals for the facility to achieve in persuit of this, including:

- eliminating the use of fossil fuels

- providing a comfortrable, healthy workplace for staff, including thermal comfort and access to daylight

- being a good desert citizen by addressing water scarcity

- optimizing operational and embodied emissions, including internal transportation

- providing adequate daylight, outdoor views, and biophilic connection to the landscape from the factory floor

We identified design concepts to meet the above goals, and the illustrations produced for this project were done over conversations with colleagues to effectively communicate and promote their pursuit.

- eliminating the use of fossil fuels

- providing a comfortrable, healthy workplace for staff, including thermal comfort and access to daylight

- being a good desert citizen by addressing water scarcity

- optimizing operational and embodied emissions, including internal transportation

- providing adequate daylight, outdoor views, and biophilic connection to the landscape from the factory floor

We identified design concepts to meet the above goals, and the illustrations produced for this project were done over conversations with colleagues to effectively communicate and promote their pursuit.

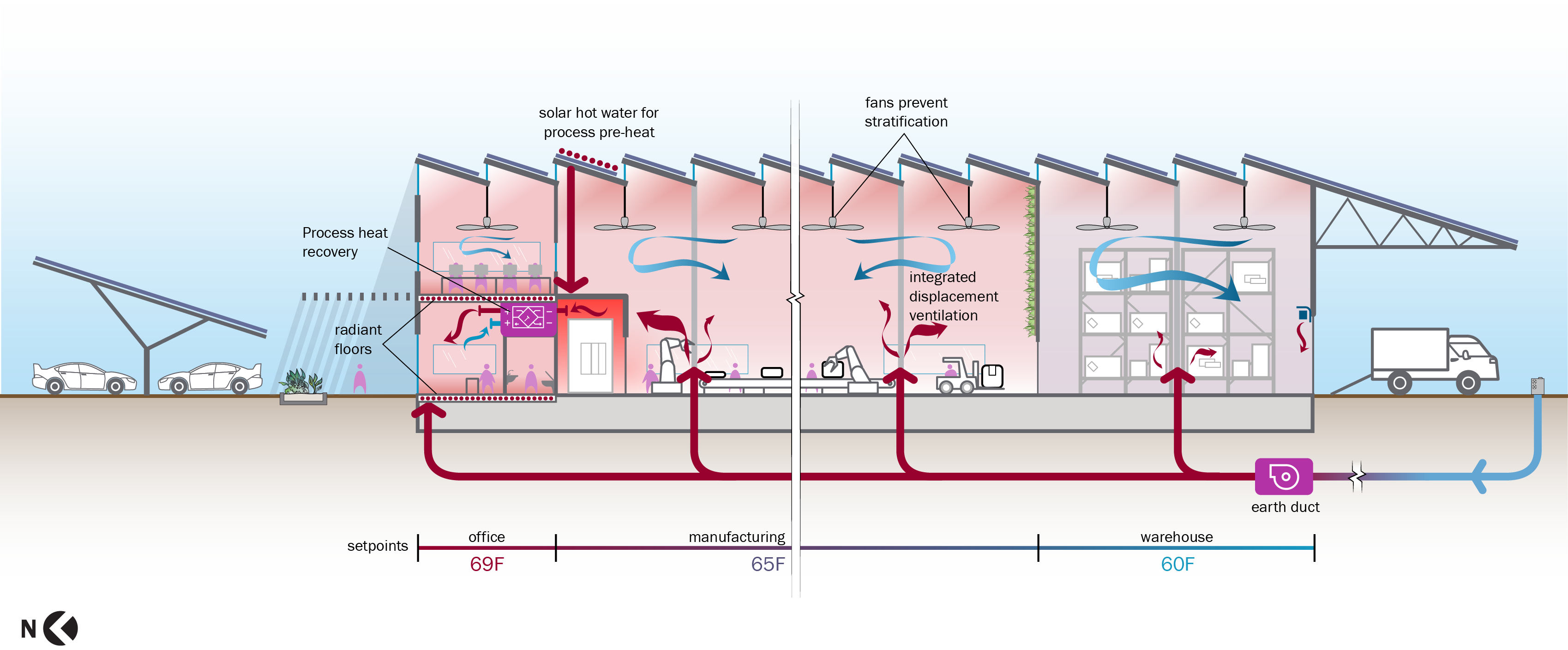

Winter Conditioning Strategies

Building conditioning (heating & cooling) is likely to be a large portion of the project’s energy use. The building will be a high volume space that may have large amounts of waste heat generated in the manufacturing space (from equipment, ovens, etc.) The winter conditioning concept aims to reuse waste heat wherever possible, and supplement it with effi cient heating systems that eliminate the use of fossil fuels.- Condition each zone the minimum amount based on its needs, which may be comfort conditioning and/or specialized needs for sensitive equipment

- Heat supplied low in the space warehouse and

manufacturing space, to heat people where they are rather than heating the entire volume.

Supply air through displacement vents (ideally integrated with the structural columns)

- Ceiling fans to prevent heat stratifi cation in

tall spaces, and force the hot air back in the occupied zone

- Radiant floor system in the office spaces

- Ventilation air pre-conditioning through earth

ducts. Earth ducts are concrete pipes buried on the site which use the temperature of the

ground to pre-heat & pre-cool incoming air

- Ground source heat pump system to support

a baseload of hot and chilled water for space cooling, heating and process uses in lieu

of traditional chillers and boilers. Further evaluation of the building loads will be

required to determine if the system will be

balanced.

- If ground source heat pumps are not viable,

efficient chillers and air source heat pumps are a great all-electric alterative. If simultaneous

heating and cooling are needed, heat recovery chillers may be effective.

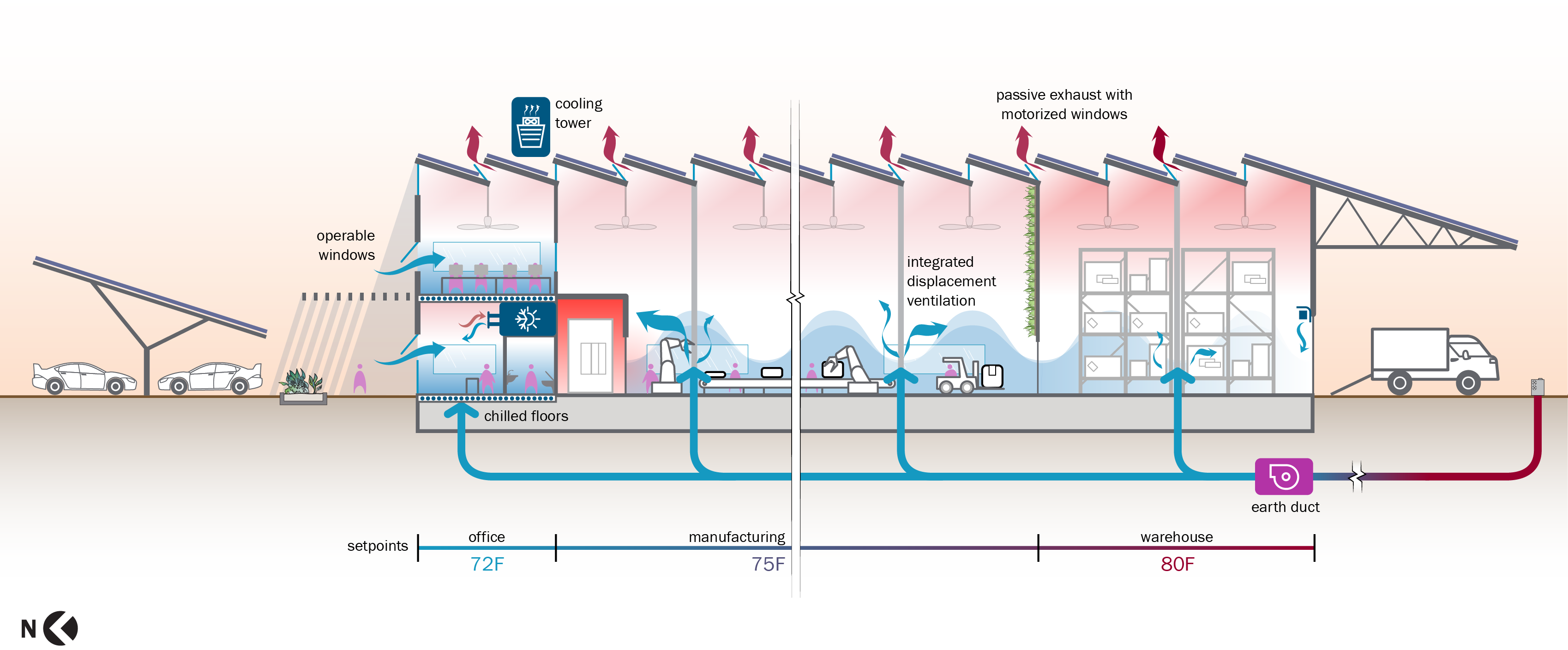

Summer Conditioning Strategies

Building conditioning (heating & cooling) is likely to be a large portion of the project’s energy use. The building will be a high volume space that may have large amounts of waste heat generated in the manufacturing space (from equipment, ovens, etc.) The summer conditioning concept aim to utilize low energy systems to cool people, rather than cooling the entire volume of space, taking also advantage of New Mexico’s diurnal temperature swings.- Chilled floor system in the offi ce spaces, and backup chilled beams can be a great combination of low energy systems.

- Night fl ushing of the exhaust air via motorized

roof openings and operable windows when the night temperatures are low.

- Water-to-water heat recovery chillers can be

coupled with process equipment needing heat, while building requires cooling.

- Ventilation air can be pre-cooled using the

same earth duct network utilized in the winter

months.

- Cold air can be supplied through displacement

vents (ideally integrated with the structural columns) at the occupant’s level.

Displacement ventilation air is often supplied in higher temperature and lower speeds

than traditional Air Handling units, thus; it

conserves energy.

- As mentioned in the heating section, a ground

source heat pump system can support a baseload of chilled water for space cooling in

lieu of traditional chillers.