Living Wall Prototyping

What

Where

When

For

Where

When

For

Irrigation Research

Berkeley, CA

2020

Habitat Horticulture

Berkeley, CA

2020

Habitat Horticulture

Habitat Horticulture wanted to research capillary performance of different textiles in order to inform and potentially innovate on their current living wall systems. The research began with experiments of capillary uplift with a wicking textile that would be a compliment to the main synthetic substrate material, but the research quickly expanded to include experiments evaluating the potential for a top-down gravity wicking material instead of bottom-up. Using gravity to passively irrigate the plants, this solution shows the potential to save energy typically consumed by pumps in a more conventional hydroponic system. I personally designed, built, conducted, observed, and recorded the experiments for evaluation. I also selected the most promising materials for both substrates and wicking layers and built/installed six different systems with different material compositions and irrigation methods. These 6 systems will be observed by Habitat Horticulture for longer-term assessments of performance.

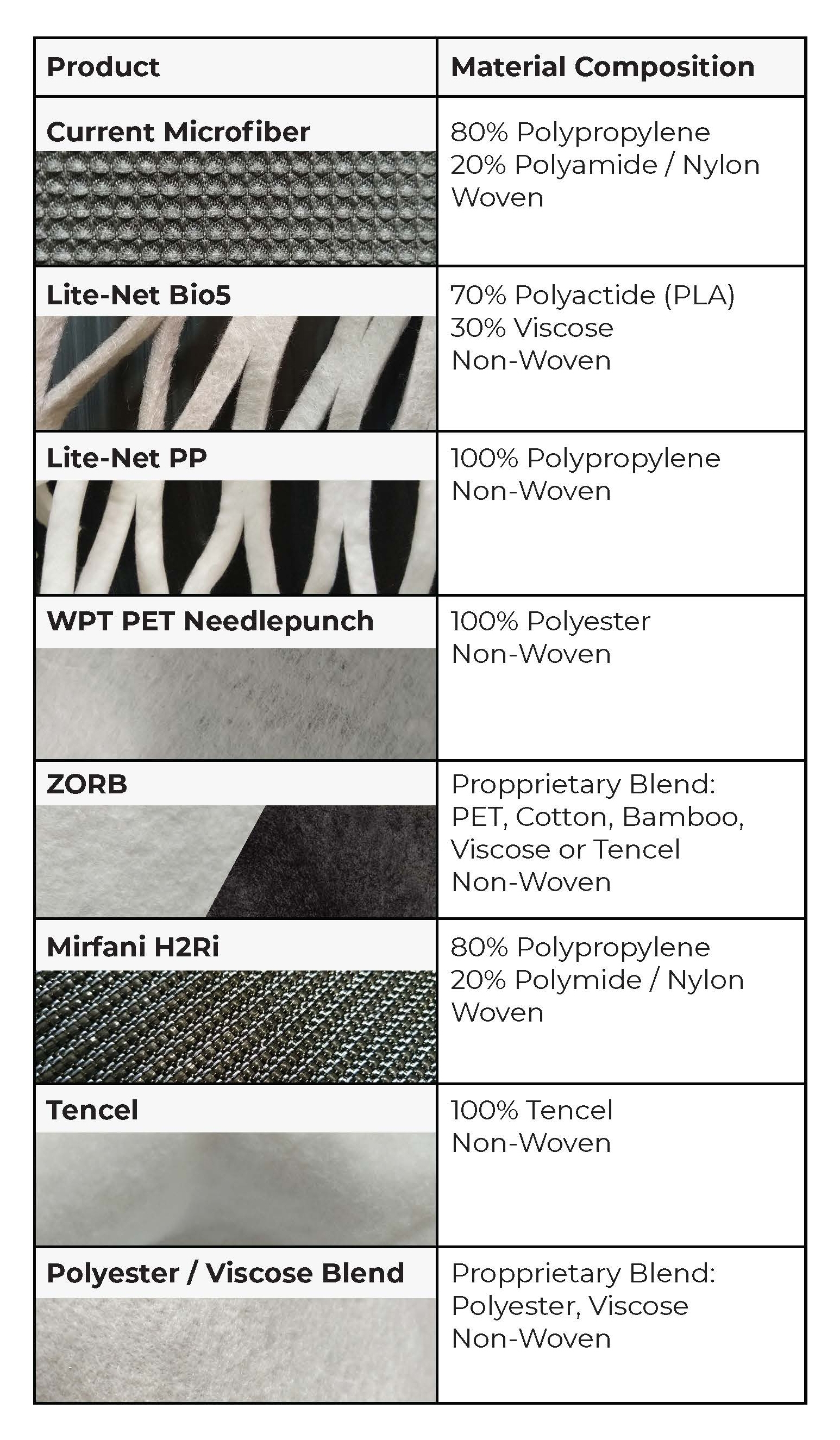

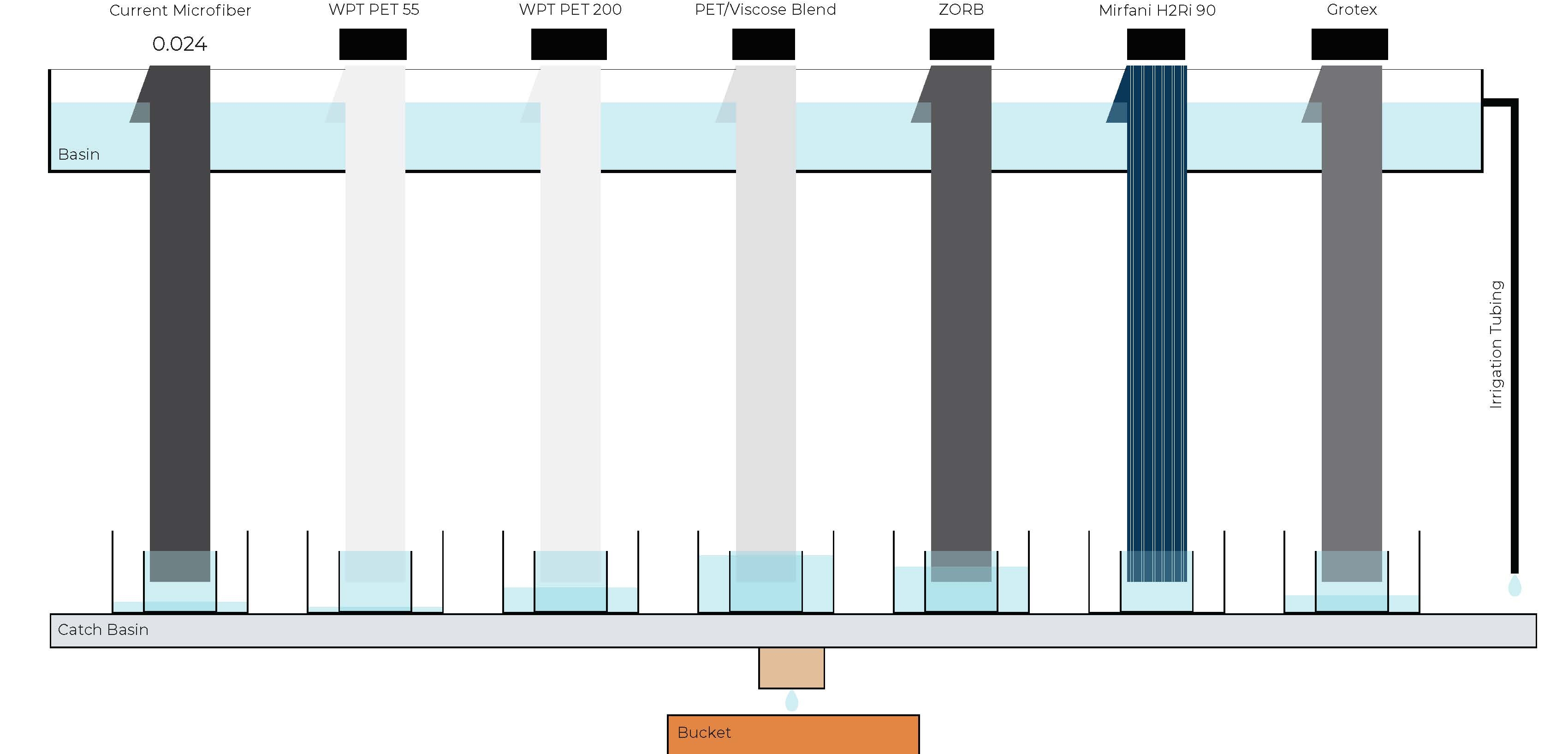

4” wide strips of material and suspended from a basin where the ends are submerged. This water level is kept at a constant height through repeatedly filling the basin where excess water pours out through a tubing fixed in its side. The strips of materials are hung down 30” into individual containers that are pre-filled with water to maintain a constant head pressure. Conducted water overflows into larger individual containers and is weighed after 1 hour. This weight was used to calculate the gallons per hour per linear foot of material submerged in an overhead basin. Materials chosen based on which ones could conduct water to their base before submerging ends in containers.![]()

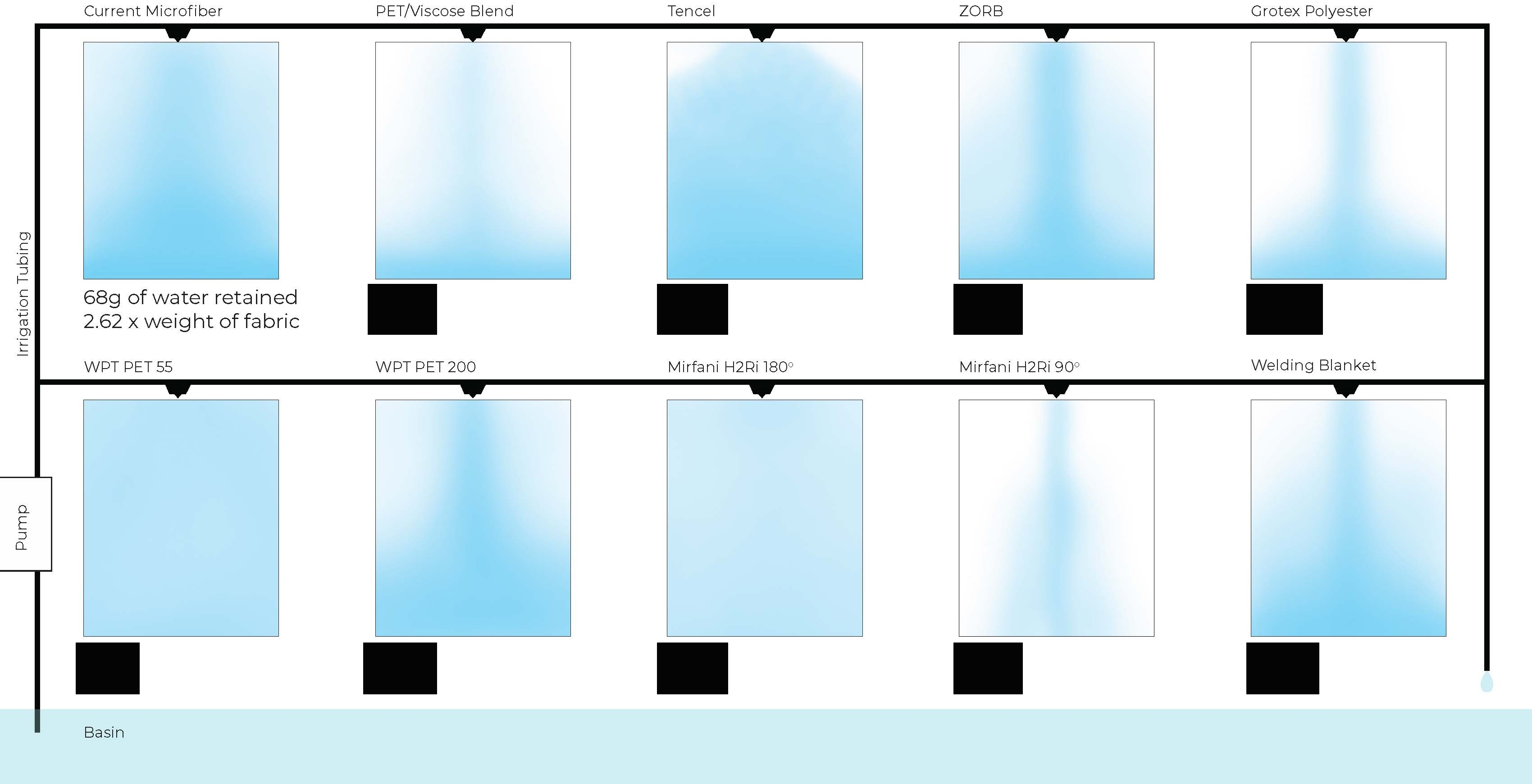

10” x 12” sheets of fabric are hung and centered under single emitters to observe how they channel water during irrigation and retain/distribute it over time. The depictions below are the long-term moisture distribution behaviors exhibited by the materials. Considering how their distribution behaviors vary and how a real-world installation would have a more equitable moisture distribution with more emitters, their maximum retention capacities were measured by removing, saturating, and hanging the fabric to allowing them to reach field capacity, after which they were weighed. Data on weight from manual saturation is provided in full spreadsheet.![]()

1. Half the quantity of emitters will help test the lateral wicking ability of the proprietary nylon fibers in the H2Ri geotextile, and how well that could synergize with the retention abilities of the Grotex growing medium. The geotextile’s orientation of wicking fiber will also help prevent water from rushing through, allowing less water to be pumped. Root interfacing behavior with the H2Ri should also be closely observed.

2. With the exception of Tencel, Zorb is by far the most sustainable product while also being anti-microbial, so this will test how well it could supplant the current microfiber where upward wicking is not demanded. A larger sheet will help see how the distribution and retention compares to the active irrigation tests (if water doesn’t rush through too quickly) in addition to how plant roots take to the material.

3. This non-combustible assembly will test how well water and plants take to the new carbonized welding blanket growing medium over the long-term. Without a non-combustible wicking textile, the current microfiber is used with hopes that it may be exempted considering its position sandwiched in the welding blankets. Fire-resistant plant types are recommended for planting.

4. This assembly is almost exactly the same as the current standard assembly. The only difference is the orientation of the microfiber at a 45o angle to further confirm the upward wicking potential demonstrated by initial testing. This advantage provided by a diagonal texture rather than a vertical one could provide water to an extra row of plants.

5. This is the exact same assembly as the current standard but deployed in a gravity wicking context. Because of the microfiber’s favorable performance in testing, it will be important to see how much moisture is lost by dripping from the bottom, if any.

6. All other mock-ups have a single variable changed from the standard assembly with exception of this one. Zorb is used as a gravity wicking textile with a staggered cut pattern to simultaneously create moisture check dams and pockets for plants. The only other layer is Grotex which exists behind as the sole growing medium layer, minimizing material. Material tongue should be cut and only partially submerged to balance water uptake.

2. With the exception of Tencel, Zorb is by far the most sustainable product while also being anti-microbial, so this will test how well it could supplant the current microfiber where upward wicking is not demanded. A larger sheet will help see how the distribution and retention compares to the active irrigation tests (if water doesn’t rush through too quickly) in addition to how plant roots take to the material.

3. This non-combustible assembly will test how well water and plants take to the new carbonized welding blanket growing medium over the long-term. Without a non-combustible wicking textile, the current microfiber is used with hopes that it may be exempted considering its position sandwiched in the welding blankets. Fire-resistant plant types are recommended for planting.

4. This assembly is almost exactly the same as the current standard assembly. The only difference is the orientation of the microfiber at a 45o angle to further confirm the upward wicking potential demonstrated by initial testing. This advantage provided by a diagonal texture rather than a vertical one could provide water to an extra row of plants.

5. This is the exact same assembly as the current standard but deployed in a gravity wicking context. Because of the microfiber’s favorable performance in testing, it will be important to see how much moisture is lost by dripping from the bottom, if any.

6. All other mock-ups have a single variable changed from the standard assembly with exception of this one. Zorb is used as a gravity wicking textile with a staggered cut pattern to simultaneously create moisture check dams and pockets for plants. The only other layer is Grotex which exists behind as the sole growing medium layer, minimizing material. Material tongue should be cut and only partially submerged to balance water uptake.